Technical information

| supply voltage |

400 V/ 50 Hz/ 3 phases

230 V/ 50 Hz/ 1 phase – with frequency converter

115 V/ 50 Hz/ 1 phase

115 V/ 60 Hz/ 1 phase |

| operation power |

1.1 kW |

| working speed |

8.5 m/min |

| forming stages |

7 stations |

| shortest panel length |

500 mm |

| infeed width |

240 mm – 850 mm |

| axial dimension |

approx. 170 mm – 780 mm (depending on the material) |

| infeed height |

670 mm – 870 mm (continuously variable) |

| processable materials |

titanium zinc up to 0.8 mm

copper up to 0.8 mm

aluminium up to 0.8 mm

sheet steel (galvanized and coated) up to 0.7 mm |

| dimensions (l x w x h) |

1,200 mm x 1,400 mm x 850 mm – 1,050 mm |

| weight |

220 kg |

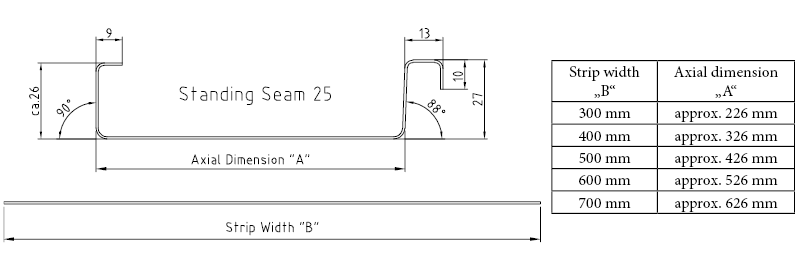

Profile information

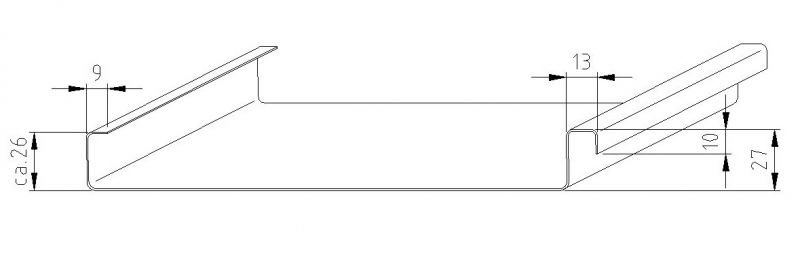

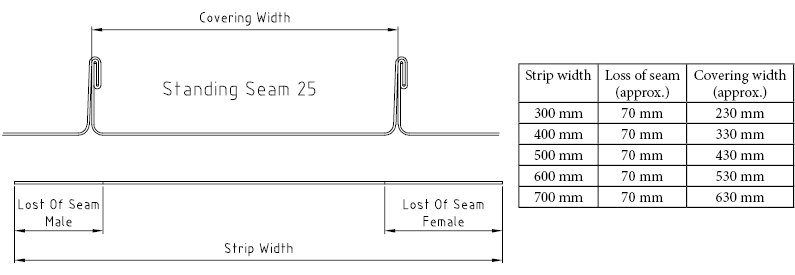

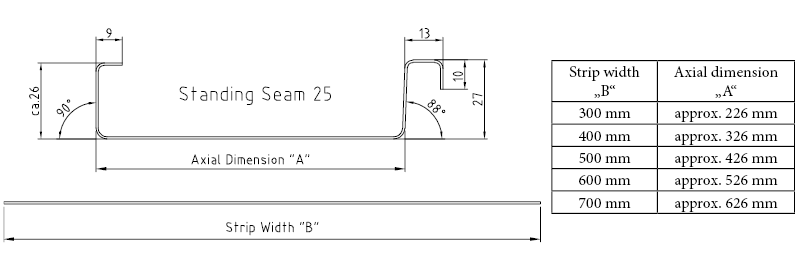

Dimensions Standing Seam 25

a) axial dimension

The corresponding strip widths result in the following profile dimension for the profile height 25 mm:

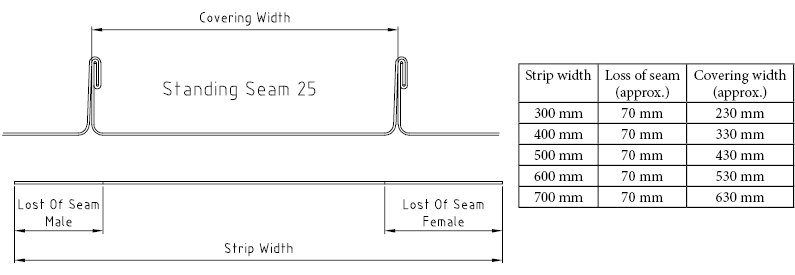

b) covering width

During installation, the resulting covering widths must be considered:

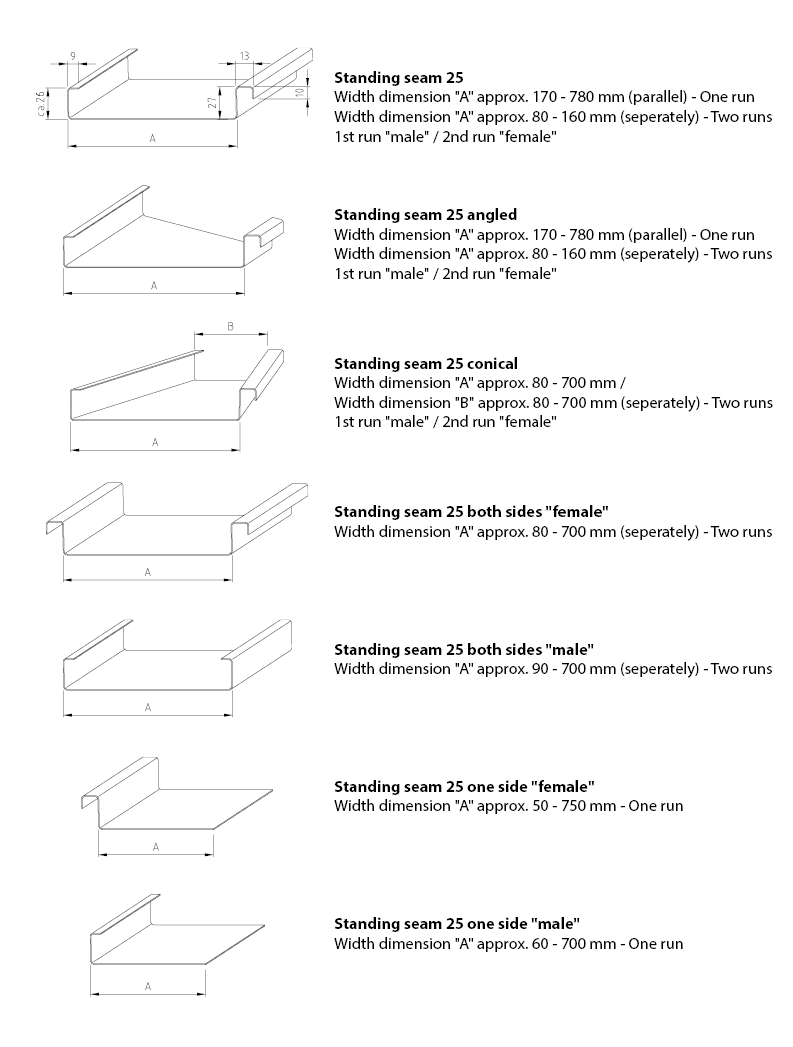

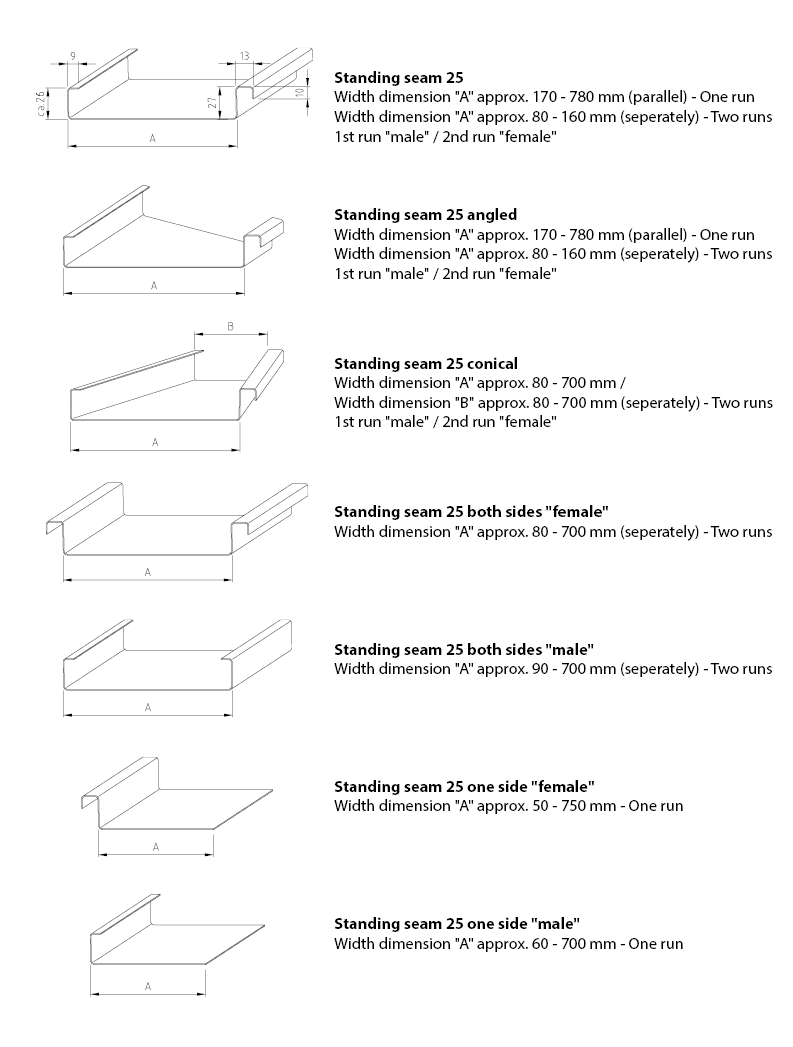

c) variants

The following profiles can be manufactured on the machine:

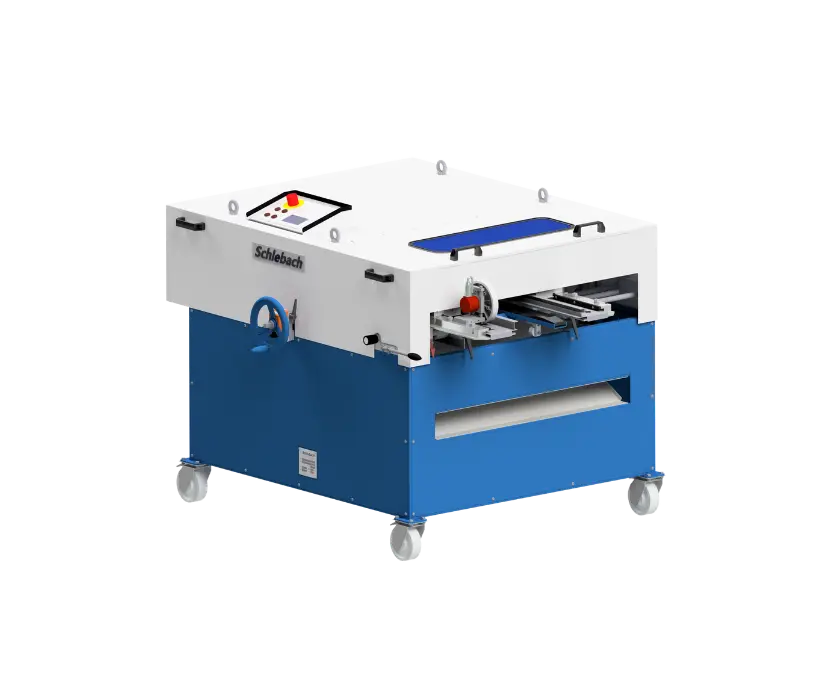

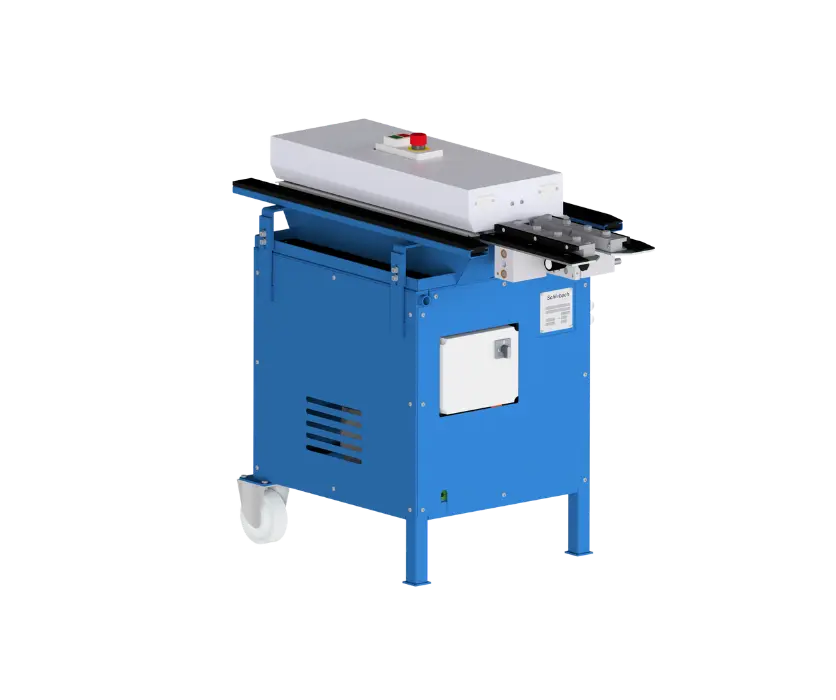

System description

Schlebach machines are characterized by the highest precision and user-friendliness. Get to know the folding techniques and backgrounds of the processing of metal.

Learn more

Laying

Learn more about laying finished sheets with a Schlebach machine.

Learn more

Accessories

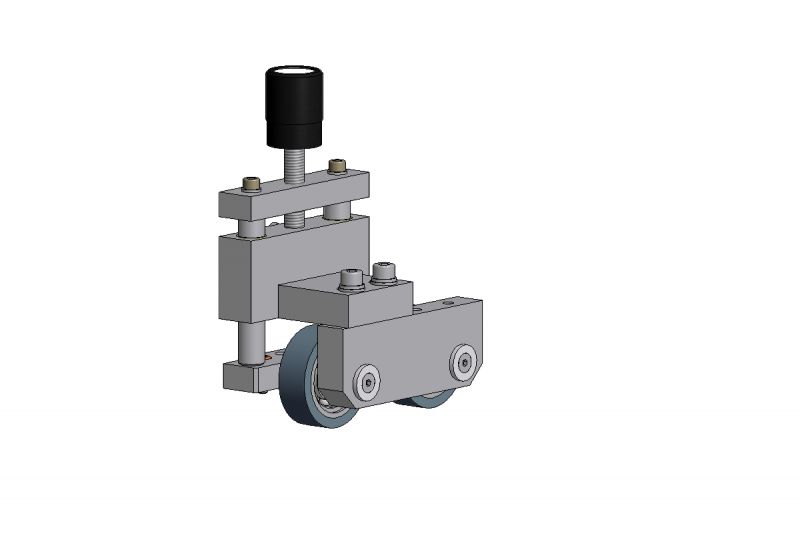

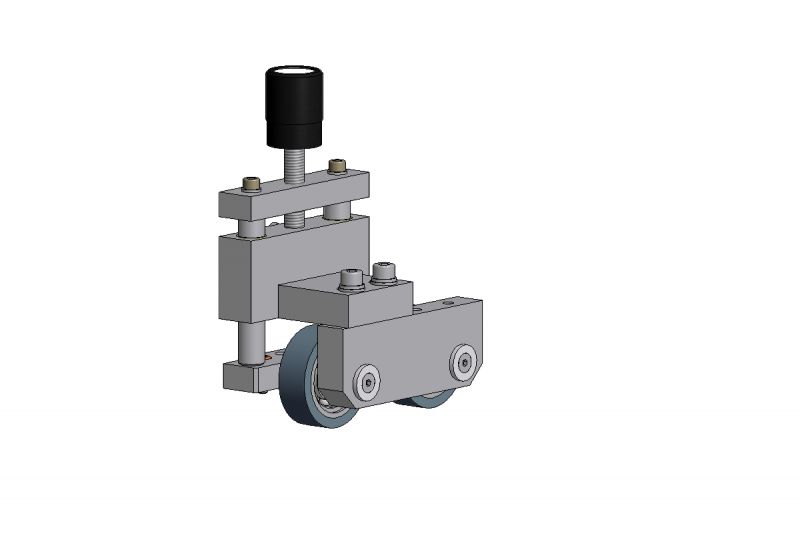

Guideboy

Additional material guide for single-sided profile shaping of panels. The installation of the Guideboy on any of the Schlebach profile shaping machine infeed guides requires little effort.

The Guideboy prevents the sheet material from shifting towards the centre of the machine during single-sided profile shaping operations. The required lateral force across the profiling direction may be adjusted by means of the directional angle, as well as an increase of the contact pressure on the sheet metal.

Damage to the material surface is ruled out by the use of high quality pressure rollers with a special rubber coating.

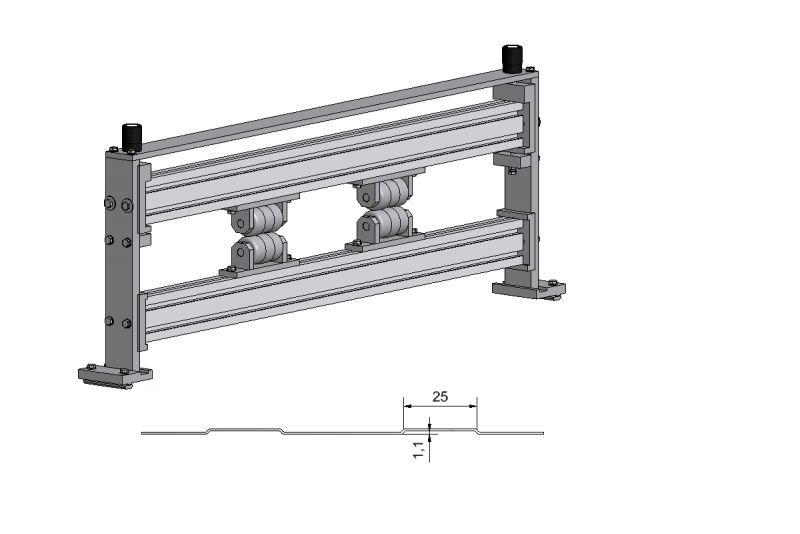

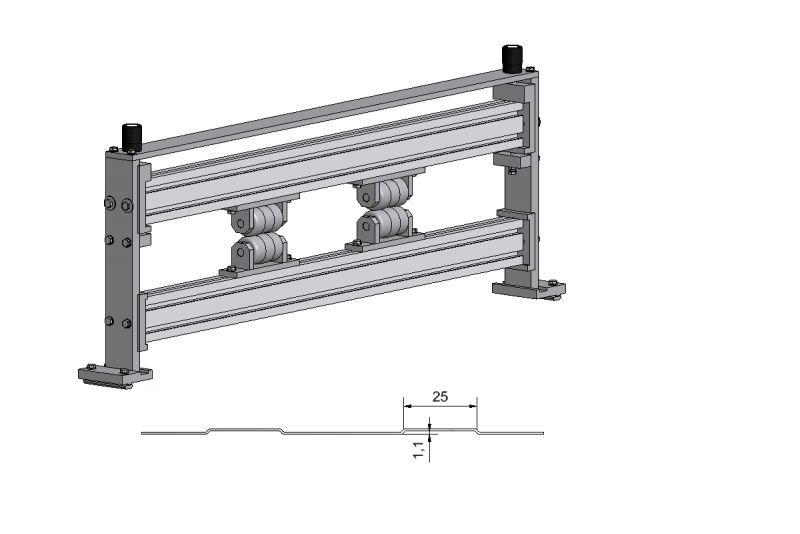

Ribbing Attachment 25 mm

Ribbing attachment assembly to shape longitudinal ribs with a width of 25 mm and a depth of approximately 1.1 mm into the visible surface of profiled panels. The ribbing attachment assembly consists of a guide unit, upper and lower ribbing rollers with brackets.

The ribbing attachment assemblies are equipped with high-quality ribbing rollers on ball-bearings to ensure maximum protection of the surface from the panels being profiled. The ribbing attachments are continuously adjustable across the profile shaping direction to ensure that the distance of the ribs that are pressed into the panels may be designed as required.

Note: The profiling of ribs is not possible on conical shapes.

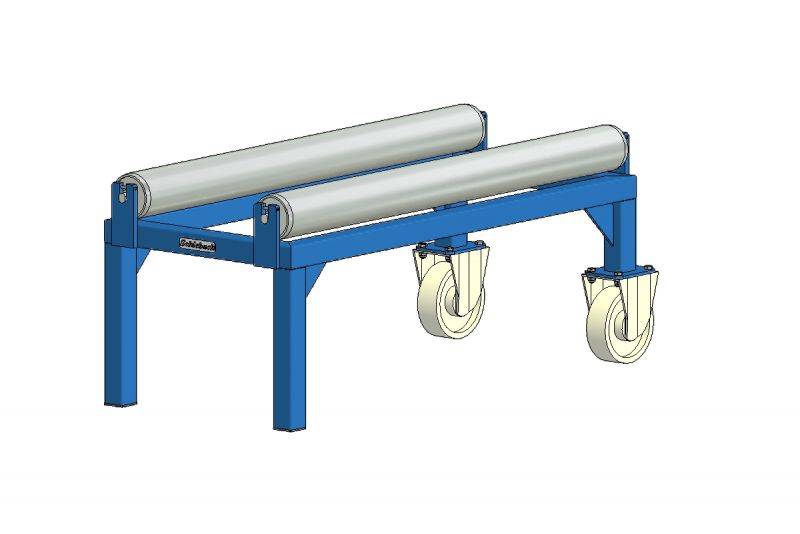

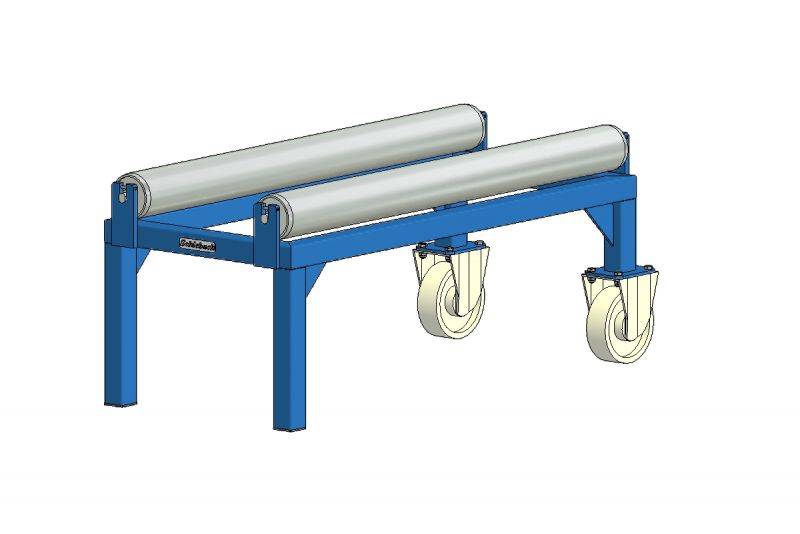

Decoiler AC

Decoiler with a maximum payload of 300 kg. Consisting of welded frames with two castors and supporting rollers on ball-bearings that are made of galvanized steel. The decoiler is optionally available with a braking device that acts on one of the supporting rollers as well as two flanges.

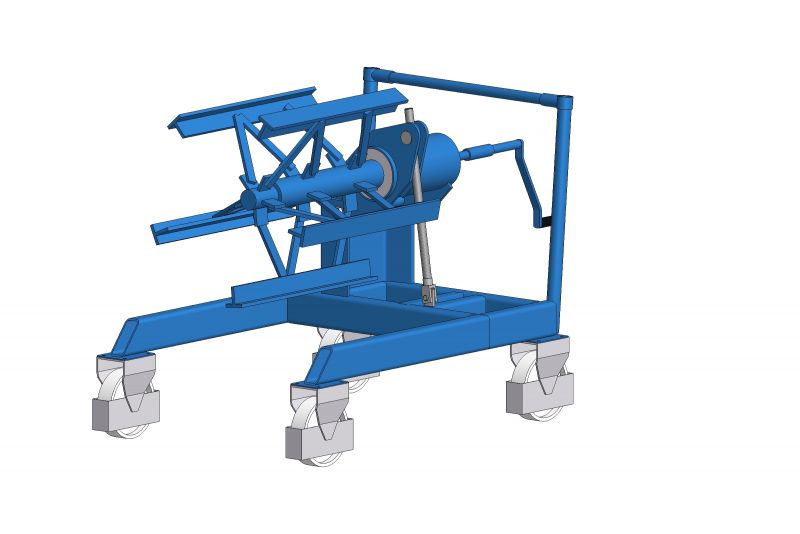

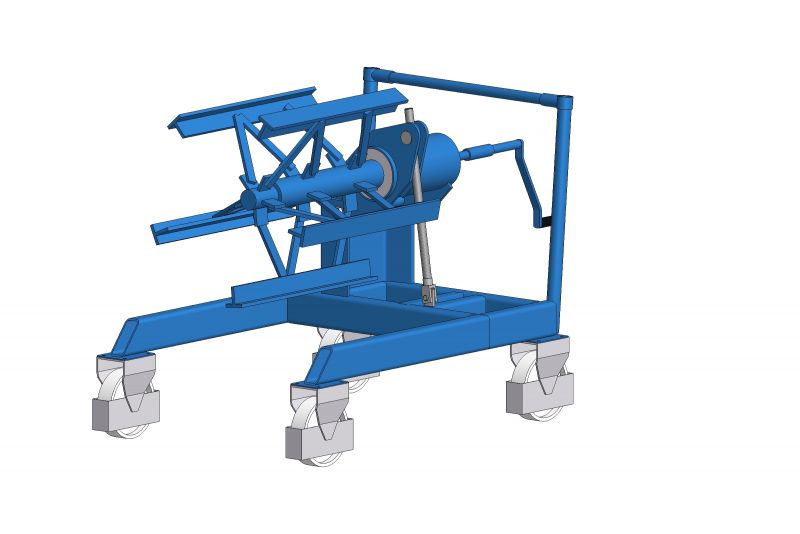

Decoiler TRANS-ASPO

The TRANS-ASPO decoiler is for fast and simple holding of 1 t coils. Due to the flying bearing and the manual height adjustment, the coil can be placed on the tensioning mandrel and tensioned manually without additional lifting equipment. The decoiler is equipped with four travel rollers (two of them with fixing brake), and can therefore be placed easily in front of the working machine.