Folding profiles

Laying

Substructure

Observe the country-specific standards, regulations and laws.

Manufacturing

Profile manufacturing by machine

For the economical production of the standing seam profile, various versions of profiling machines can be selected from the Schlebach program depending on the requirements and profile size.

For the economical production of the standing seam profile, various versions of profiling machines can be selected from the Schlebach program depending on the requirements and profile size.

The EPM-25, MINI-LIGHT, MINI-PROF and MINI-PROF PLUS profiling machines are available from the small machine program for the standing seam 25 mm. The machines of the SPM series are also used for the production of the standing seam 25 or 32.

These include, for example, the machine types SPM, SPM-RS, SPM-LM-QA60 or the fully automatic version SPA.

For larger profile heights from 38 mm to 50 mm, machines of the QUADRO series can be used.

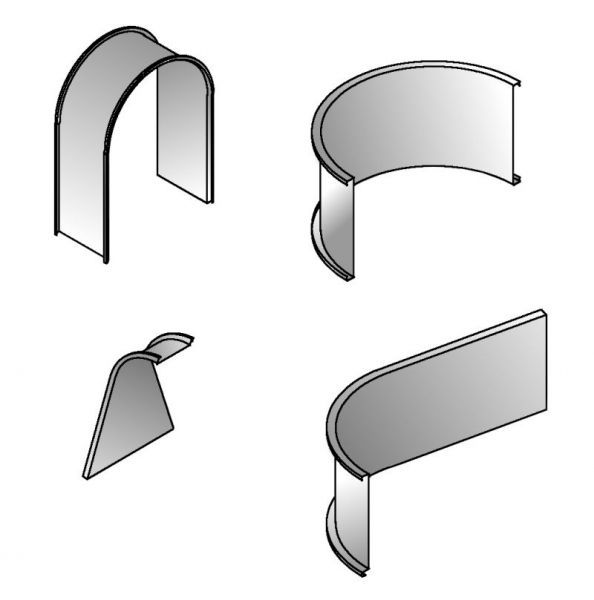

For the covering of round dormers or dome roofs, the profiled sheets must be bent convexly in a further work step before laying, depending on the radius.

Round bending is performed on an RBM round bending machine.

Mounting

Laying the profiled sheets

A distinction is made between sheet roofing with limited lengths and strip roofing with material-dependent strip lengths of up to 14 m and, in individual cases, even longer.

Depending on the material used, the corresponding manufacturer’s instructions and country-specific specifications, standards and guidelines must be observed during installation. Schlebach has issued corresponding installation guidelines specifically for the use of aluminum and stainless steel.

Fastening the profiled sheets

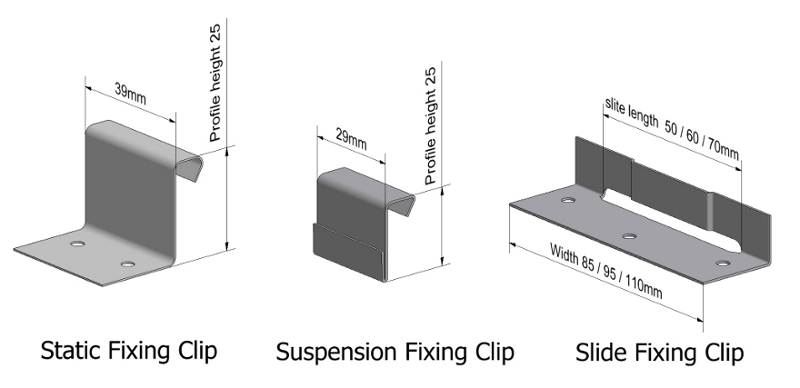

To mechanically secure the profiled sheets to the substructure, so-called clamps are used with the corresponding fasteners, nails or screws. The clamps can be designed as fixed clamps or as sliding clamps to absorb longitudinal expansion.

Depending on the roofing material and the construction of the substructure different versions are available for the clips and the installation materials. Further information may be available from the following suppliers:

Bracket systems:

www.rheinzink.com

www.rees-oberstdorf.de

www.rooftec.de

www.metalroofclips.com

www.protectum-haften.de

www.sfsintecusa.com

Fasteners:

www.sfsintecusa.com

www.fixfast.de

The number and spacing of the clips must be designed for local conditions with regard to wind loads on the building. For this purpose, the appropriate proof must be provided and country specific standards and guidelines taken into account.

Fastening the profile sheets

After the fastening of the profile sheet by means of clips, the overlapping female side is placed on the side of male side of the profile and folded in. Depending on loading and the technical specifications the seam can be produces as a simple angle seam or a double standing seam joint.

This may be accomplished by means of manual seamer or driven seaming machines.

Schlebach offers the seamer FLITZER, PICCOLO or SPIDER.

Depending on the material and type of fold, the machines can be equipped with different folding rollers.

The design of seams, roof edge terminations and openings

For standing seams there are appropriate solutions catering for the different seam types.

Observe the guidelines provided by the material manufacturer and the relevant technical rules and regulations.

For round eaves trim, Schlebach offers two mechanical and economic solutions, KLS and EHA.

Other seams and terminations also produced by the corresponding folded flashing. Production takes place mostly on manual or CNC bending machines.

Materialien

Profiles are predominantly manufactured from cold rolled thin sheets and strips of stainless steel, steel, titanium zinc, aluminium and copper having a thickness of less than 1.0 mm.

www.rheinzink.com

www.kme.com

www.vmzinc.com

www.prefa.com

www.nedzink.com

www.aperam.com

www.ssab.com

Schlebach in perfection.

What makes our machines stand out

In the foreground of our company philosophy is the motto “Everything from a single source”. From the idea, the planning, the development and the production to the service: at Schlebach you will find everything under one roof. This guarantees you maximum performance with a high standard of quality.

User-friendly

Powerful

Maximum precision