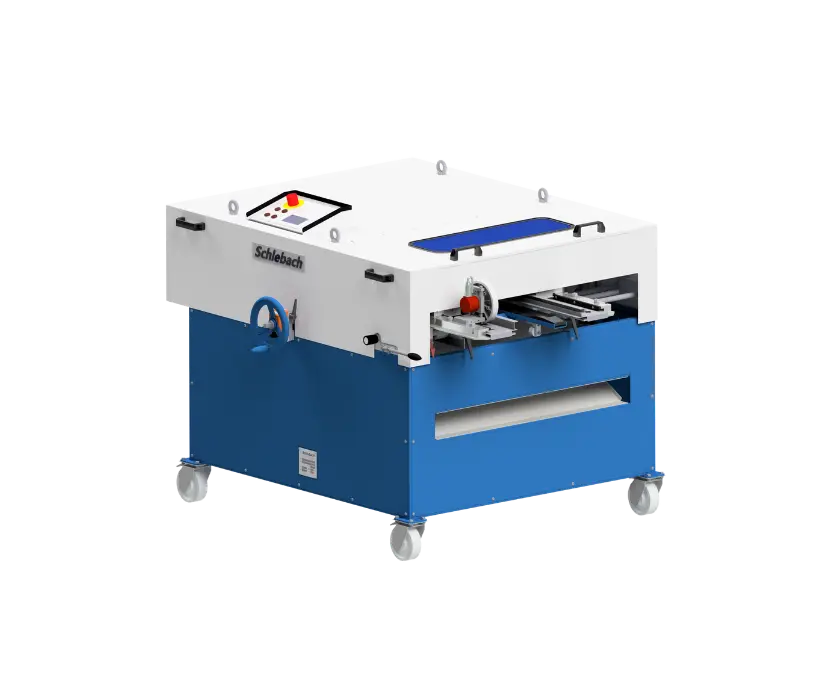

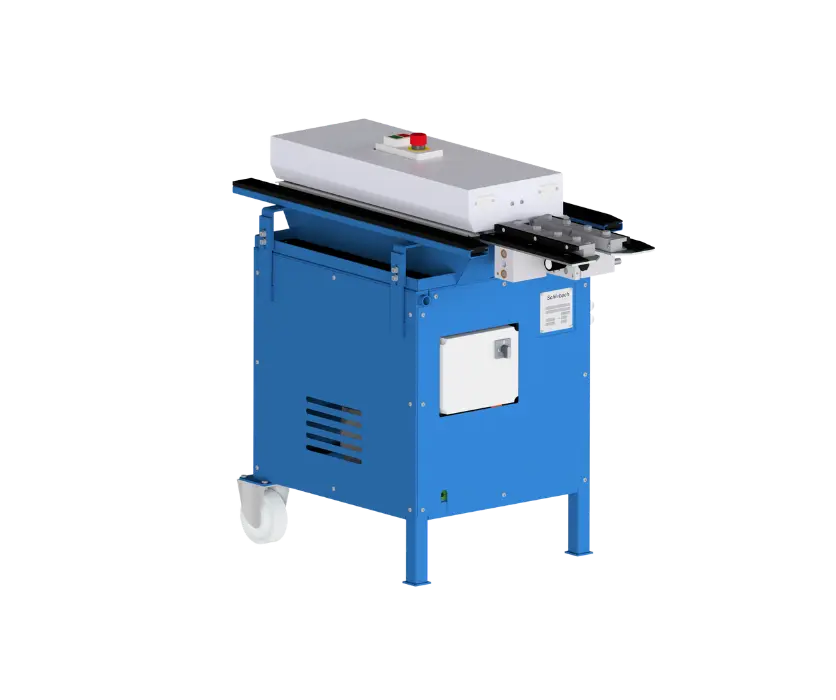

Compact machine for producing double standing seam profiles 25 from blanks, cut lengths or directly from the coil with electromechanical length measuring device with a scale in centimetres, a driven belt feeder and a hand operated roller shear to execute manual cross-cuts.

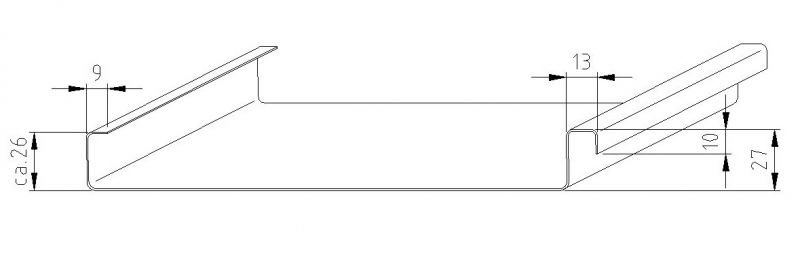

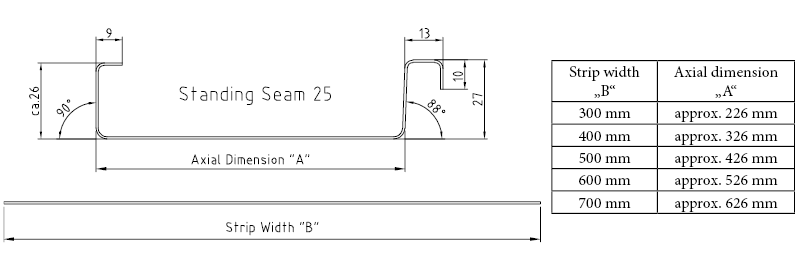

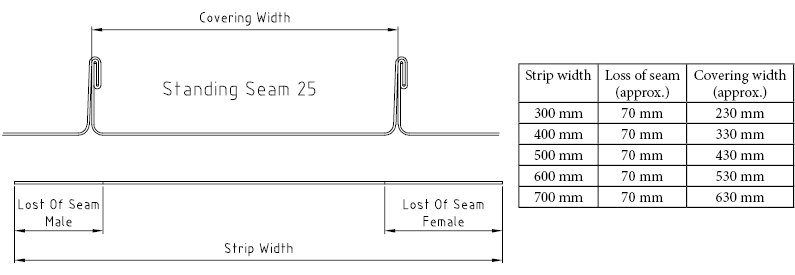

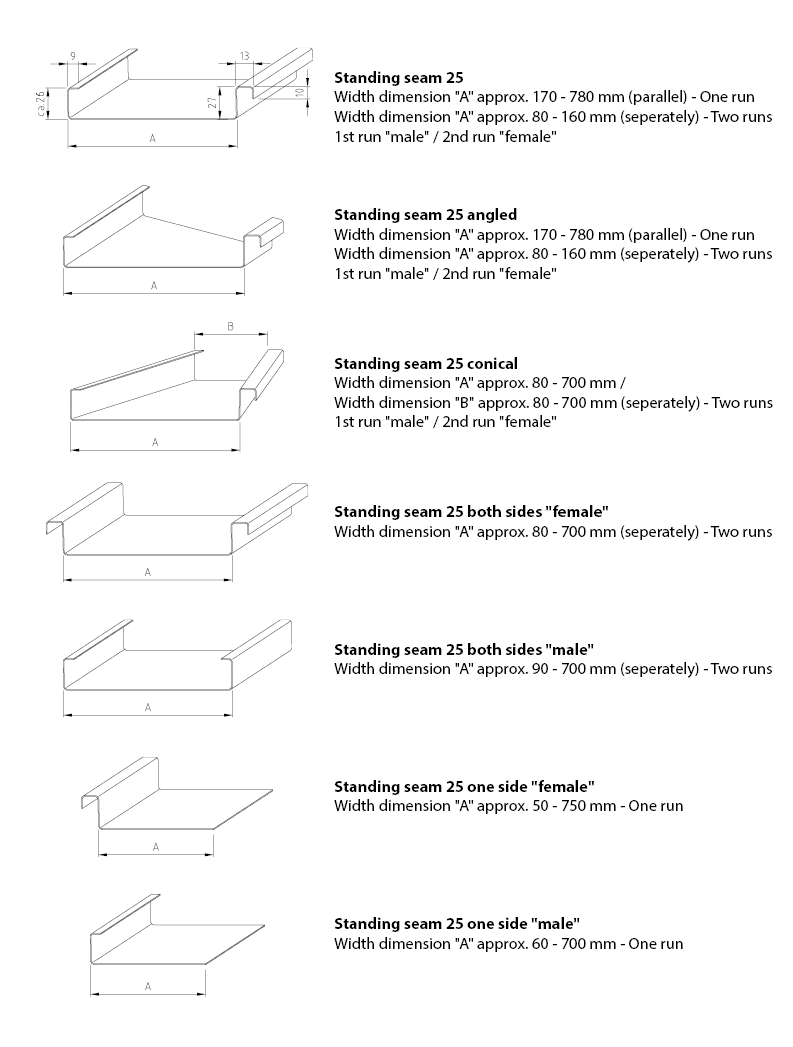

profile dimensions

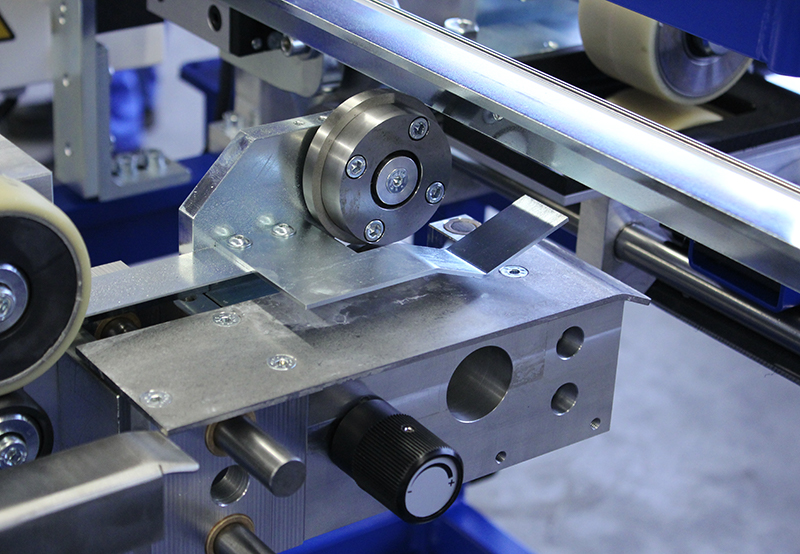

manual cross-cutting roller shear RS

longitudinal cutter LS (optional)

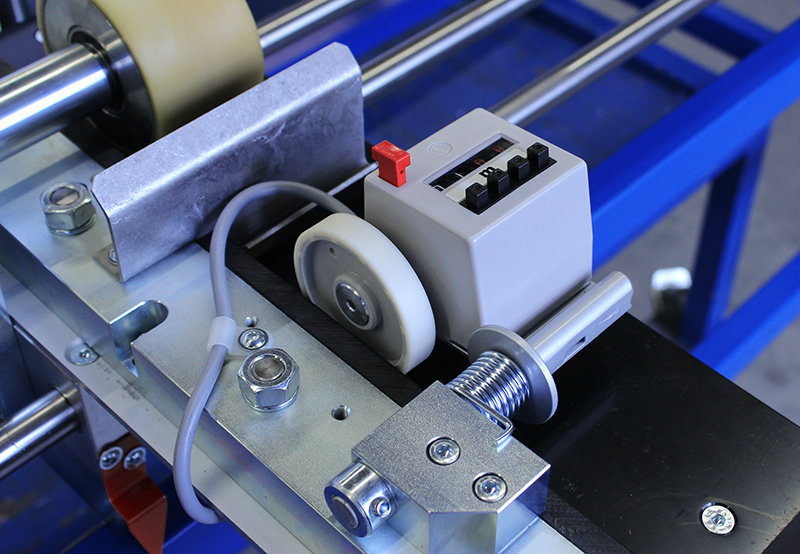

electromechanical length measuring device

Features

- compact version with all necessary accessories

- mechanical length measuring device in cm-gradiation, tolerance 1 cm – 2 cm

- roller shear RS to perform manual cross cuts ahead of profile shaping

- roller blades LS to perform longitudinal cuts of parallel fitting panels ahead of profile shaping

- decoiler for 300 kg coil weight

- parallel sheet metal is produced in a single work cycle

- minimum panel length 500 mm (depending on the material)

- stepless width adjustment from 240 mm – 850 mm

- tapered, conical or fitting panels in two work cycles

- smallest axial dimension 80 mm when producing single-sided profiles

- movable on four castors

- height adjustable, leading to comfortable working conditions

Video

Downloads

More products and solutions

Profiling machine MINIPROF PLUS RSM

Our MINIPROF PLUS RSM profiling machine - with digital length measurement in mm graduation, a driven strip infeed and a motor-driven roller shear for cross cutting before profiling

Profiling machine MINIPROF

Our profiling machine MINIPROF - suitable for beginners or as a second machine for the production of double lock standing seam profile 25

Profiling machine MINI LIGHT

Our profiling machine MINI LIGHT - for the production of double lock standing seam profile 25 from blanks or sheet material in one pass

Profiling machine EPM 25

Our EPM 25 profiling machine - for double lock standing seam profile 25 and one-sided profiling in two operations

Additional material guide for single-sided profile shaping of panels. The installation of the Guideboy on any of the Schlebach profile shaping machine infeed guides requires little effort. The Guideboy prevents the sheet material from shifting towards the centre of the machine during single-sided profile shaping operations. The required lateral force across the profiling direction may be adjusted by means of the directional angle, as well as an increase of the contact pressure on the sheet metal. Damage to the material surface is ruled out by the use of high quality pressure rollers with a special rubber coating.

Additional material guide for single-sided profile shaping of panels. The installation of the Guideboy on any of the Schlebach profile shaping machine infeed guides requires little effort. The Guideboy prevents the sheet material from shifting towards the centre of the machine during single-sided profile shaping operations. The required lateral force across the profiling direction may be adjusted by means of the directional angle, as well as an increase of the contact pressure on the sheet metal. Damage to the material surface is ruled out by the use of high quality pressure rollers with a special rubber coating.