Rhombic-clad fasade system

Laying

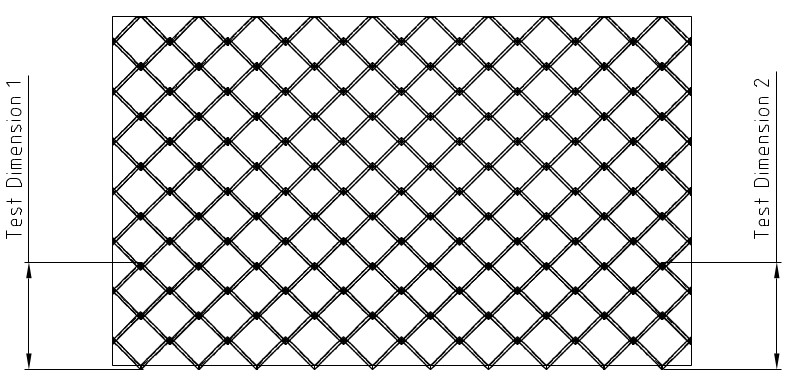

Planning

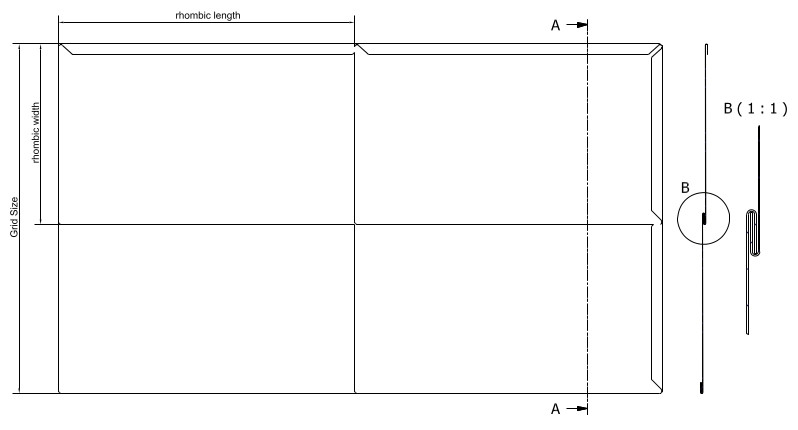

Unlike building facades that are based on double standing seam technology or other cladding solutions, the rhombic panelling system requires detailed advanced planning that depends on the respective element size. This detailed planning and organization of the facade is not necessary for the installation of small rhombic tiles. The small elements are individually adapted to the circumstances and installed.

The use of large rhombic systems requires appropriate planning, because on-site modifications and changes can only be implemented with considerable effort, especially on seams, terminations and openings. In addition to an appropriate sub-structure along with the selection of the associated fasteners, the facade must be divided into precise areas using accurate measuring techniques. In addition to the manufacturer’s instructions local standards and guidelines must be observed!

The classification in the light of overlap widths and should be entered into drawings and numbered, as they also serve as the basis for subsequent production of rhombic elements in the workshop

Planning also includes optimum positioning and anchoring of the scaffolding. Taking into account occupational safety, it must be ensured that rhombic element installations require various scaffolding anchors to be released and moved, since these anchors cannot be enclosed until the final stages as, for instance, when installing panels.

Substructure

The requirements of the material manufacturer, system supplier and local standards and guidelines must be observed.

Manufacturing

In facade construction the production and assembly preparation is executed predominantly in the workshop and only infrequently on site.

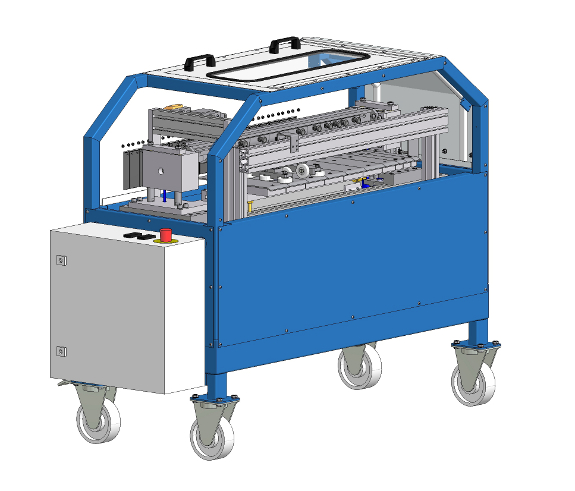

Schlebach offers a flexible combination of different machines from Schlebach program that provides a practical and inexpensive manner to prefabricate the different rhombic elements.

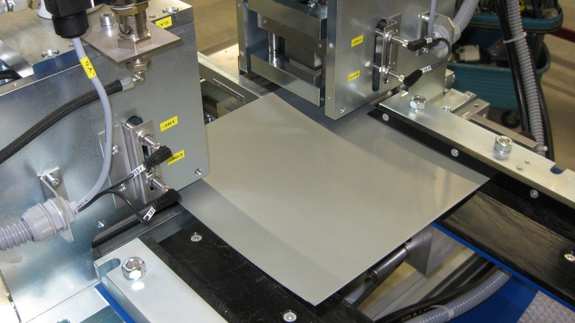

First the cut sheets for the rhombic elements are produced on the slitting system, for example type SLT400:

Then, using the notching station AKQUAD, the cut sheets are notched on the corners using appropriately equipped tools. For this purpose, pre-set depth stops simplify the work. The notching process is triggered by means of an ergonomic foot switch.

Forward and backward bends are then prepared on the folding station of the EHA or on the folding mechanism UKST. Both machines can be equipped with supports and bending segments, which were developed specifically for the requirements of rhombic production and that are available as an option.

Connecting profiles and the finishing profiles are produced by means of folding presses or swivel bending machines.

The protective film applied by the manufacturer should be removed immediately after installation.

Installation

The explanations presented below are examples only and may differ, depending on country-specific standards and guidelines. Schlebach does not accept any liability or give any guarantee for their validity, accuracy and completeness.

Mounting the connecting profiles

Before you can start the actual installation of rhombic elements you have to install the connecting profiles around window frames and other openings or corners.

Installation of the rhombic elements

It is of particular importance to ensure that the orientation and position of the first rhombic element is correct.

Due to the drop-in system, the placement of the elements is basically performed from the bottom to the top to avoid water ingress in joints.

The insertion side of any further rhombic elements is inserted into the pocket side of the installed rhombic elements and fastened indirectly with the welt joints to the fold on the pocket side.

This type of indirect attachment can absorb longitudinal expansions very well.

As a manufacturer or supplier of welt joints we can, for example, mention:

www.sm-systeme.de

www.gadorosi.de

www.rees-oberstdorf.de

www.attinger.de

www.rheinzink.de

Use only tested and approved construction screws or nails as fasteners.

The following source may be mentioned as fasteners for the welt joints, for example:

www.sfsintecusa.com

www.fixfast.de

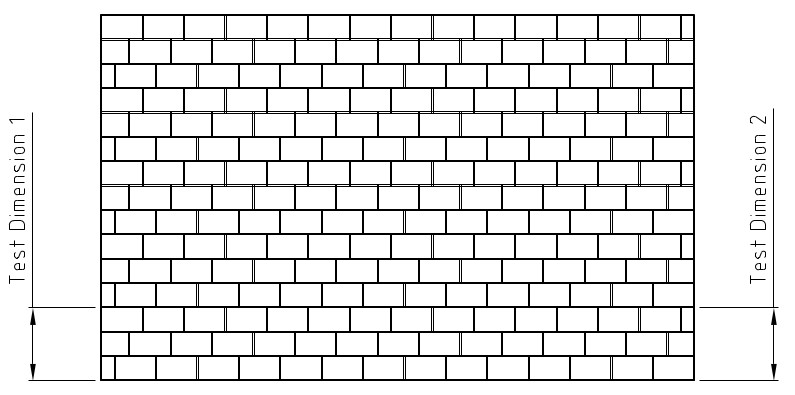

A defined pitch should be used in the assembly of large rhombic systems

Generally, it is not necessary to insert additional sealing elements into the joints and connections.

To avoid creeping inaccuracies, the grid dimensions of the installed rhombic elements should be checked again after no more than three large rhombic elements.

Installation of the finishing profiles

The same instructions apply to the finishing profiles as for the connecting profiles and other folded elements. Here additional structural profiles may be required to reinforce the substructure.

It is also necessary to ensure proper bolted and, wherever possible, concealed joints by means of suitable chamfers.

Schlebach in perfection.

What makes our machines stand out

In the foreground of our company philosophy is the motto “Everything from a single source”. From the idea, the planning, the development and the production to the service: at Schlebach you will find everything under one roof. This guarantees you maximum performance with a high standard of quality.

User-friendly

Powerful

Maximum precision