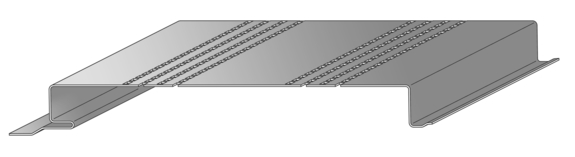

facade panels

Technical data

Dimensions

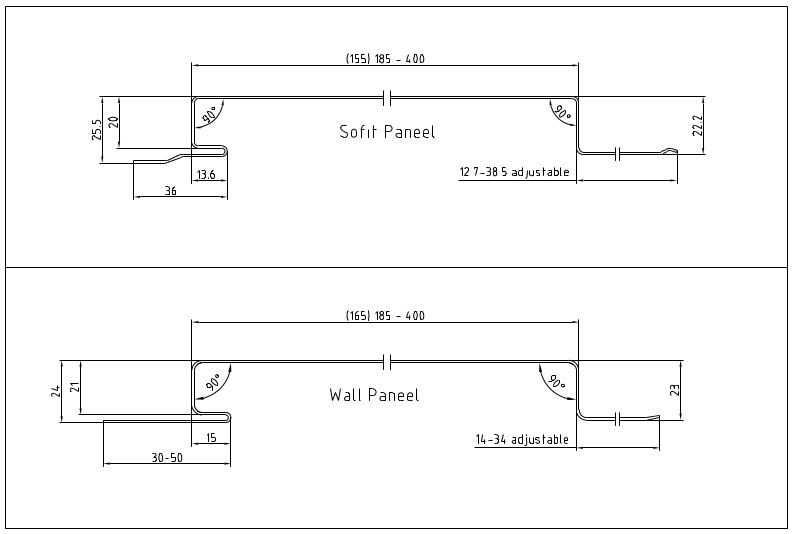

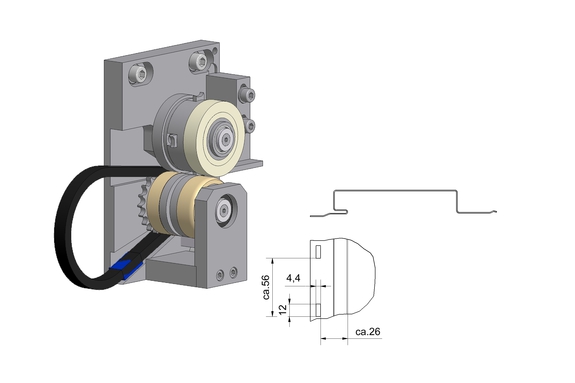

The following profile dimensions result for the two panel types:

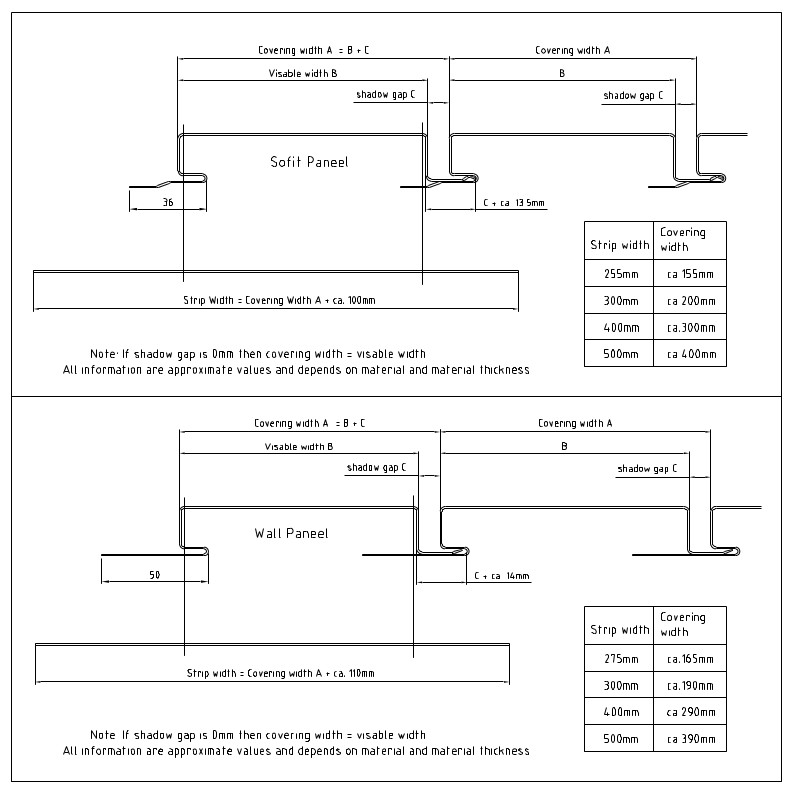

During installation, the resulting covering widths must be considered:

The max. sheet lengths and panel widths to be installed depend on the material. They are subject to the corresponding manufacturer’s specifications and installation instructions!

Versions

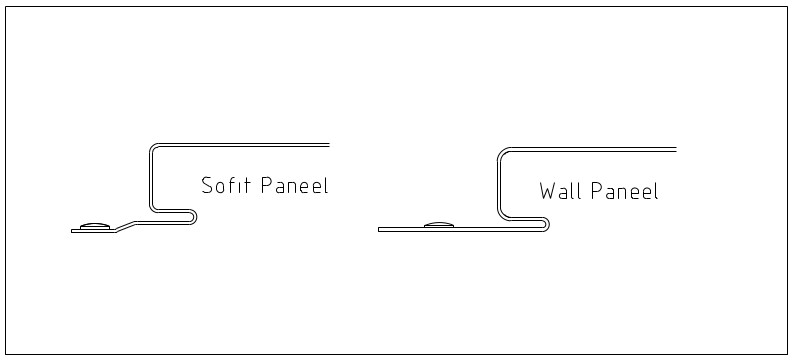

The two panel types “Soffit panel” and reveal panel “Prof88” differ in the pocket side and the radius of the profile. The stepped structure of the mounting leg of the Soffit panel on the pocket side creates additional space for the fasteners (screws, nails or rivets).

On both profiles, the width of the shadow gap can be varied as an additional optical design technique:

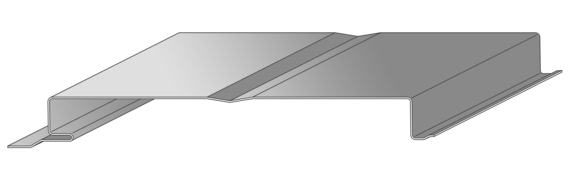

Shaping of ribs or beads represents another optical variety.

For rear ventilation purposes, visible surfaces can be provided with perforations.

To stabilize the panels they are also often notched on the two profile ends to bend the front end (note requirements of the material’s manufacturer).

For horizontal installations, it is possible to insert notches into the profile area at 90° corners of the building to create the required installation solutions.

Note:

To prevent damage the use of edged corner profiles may be a better solution for building corners, especially at ground level.

Rounded connecting profiles and finishing profiles for round building geometries with vertical installations can be obtained from manufacturers who have specialized in bending round profiles (e.g. www.krehle.de). These manufacturers also offer rounded panels for horizontal installations.

To fasten these panels to the substructure the mounting legs can optionally be punched with slotted holes.

Panel profiles are predominantly manufactured from cold rolled thin sheets and strips of stainless steel, steel, titanium zinc, aluminium and copper. Material thicknesses may range from about 0.6 to 1.2 mm. These dependent on the material itself, the panel width, the restrictions with regard to the manufacturing facility and the wind suction loads on the facade.

In addition, special requirements must be met regarding predominantly quiet and smooth surfaces of the facade. These require consideration of the specifications of the planner and the material manufacturer.

Choices of material as well as some system suppliers are mentioned below, e.g.:

www.rheinzink.com

www.kme.com

www.vmzinc.com

www.prefa.com

www.nedzink.com

www.aperam.com

www.ssab.com

Certification, standards and rules

Depending on the object design, the type of implementation and the location, facades are subject to various national standards and regulations, with supplements to certify structural safety.

Schlebach in perfection.

What makes our machines stand out

In the foreground of our company philosophy is the motto “Everything from a single source”. From the idea, the planning, the development and the production to the service: at Schlebach you will find everything under one roof. This guarantees you maximum performance with a high standard of quality.

User-friendly

Powerful

Maximum precision