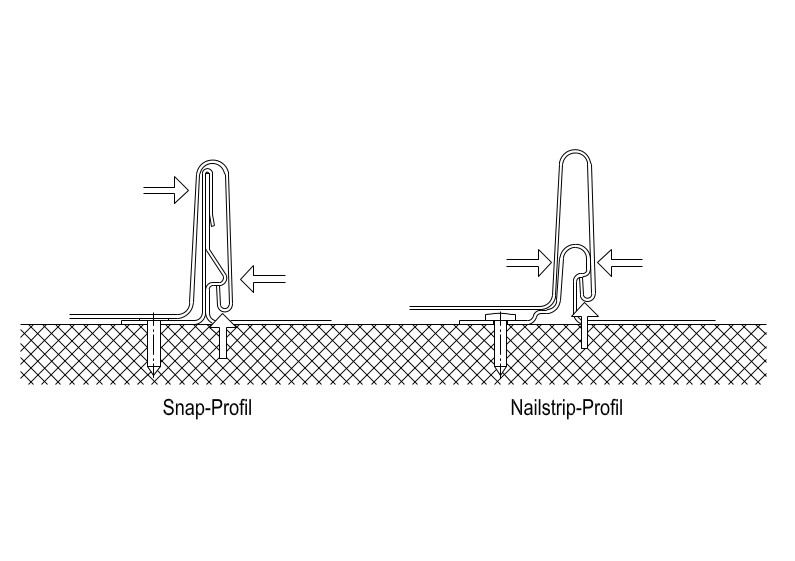

Snap / Nailstrip

Profile Description

History

Metal has been used for several centuries as the material for technically demanding roofing purposes (e.g. lead roofing of the Cologne Cathedral is about 500 years old).

Metal has been used for several centuries as the material for technically demanding roofing purposes (e.g. lead roofing of the Cologne Cathedral is about 500 years old).

In literature, the double standing seam technology as is known since about the beginning of the last century. Over the last decades, further alternatives and variations of the standing seam technology have been established globally on the basis of this technology. One of these alternatives is the so-called Snap-Profile.

Applications

The snap profile technology as well as the standing seam technology belongs to the manual seam construction technology for thin sheet roofing. It enables rainproof covering of major roof areas in commercial and residential construction. As with the classic standing seam you will obtain a finely lined pattern. In the area of openings and seams, the snap profile is often combined with the detailed solution of the standing seam.

Technology

The snap profile seam is prepared by appropriately machining the profiles of the two longitudinal edges (female and deficient male side) of the metal sheet.

After the installation on a suitably prepared substructure and after fastening the metal sheet by means of fasteners (also called “clips”) or directly into the punched holes on the side of male side of the Nailstrip profile, the next sheet is put in place and the snap profile joint between the two plates is formed by the typical „click“. The rework that is necessary for the classic standing seam technology is omitted.

The seams edge has the required holding force due to the resulting tension.

Schlebach in perfection.

What makes our machines stand out

In the foreground of our company philosophy is the motto “Everything from a single source”. From the idea, the planning, the development and the production to the service: at Schlebach you will find everything under one roof. This guarantees you maximum performance with a high standard of quality.

User-friendly

Powerful

Maximum precision